The HPGR (high pressure grinding rolls/rollers) is the core equipment of the high pressure grinding process.

The HPGR (high pressure grinding rolls/rollers) is the core equipment of the high pressure grinding process.

The machine reduces particles by compressing and crushing the feed between two counter rotating, parallel rollers with a small gap between them. This forces the rocks against each other and compresses the feed’s density to 80% of its solid volume, exceeding its compressive strength with equal pressure being applied to particles of all sizes.

It first used in the cement industry, while nowadays, also have been used in many other industries like nonferrous metal processing, ferrous metal processing, precious metal processing, etc.

Working principle

The core theory of high-pressure roller grinding is material layer crushing through high pressure. The working principle is static pressure crushing. The crushing effect is got by pressing materials between the two slowly rotating rollers. The high-pressure roll grinding implements a material layer crushing, which is the mutual crushing between materials with very high crushing efficiency. Generally, the energy consumption of high-pressure roller grinding is greatly reduced compared to impact or shear-type crushing equipment.

When the HPGR works, the two rollers make relatively slow movements. One of the rollers is fixed while the other is adjustable and is used to adjust the distance between the rollers. It is the way to control the pressure.

Normally, when the material is continuously fed to the two grinding rolls and goes through them, a certain force is given to the movable roller, thus the material is held by the two rotating rollers and moves downward with the rolls. At this time, in a certain area between the grinding rollers, the material particles will form a material layer.

With the uniform and stable high pressure (100-300MPa) from the rolls, the material particles are squeezed, cracked and crushed.

The output product size can be as low as 3mm.

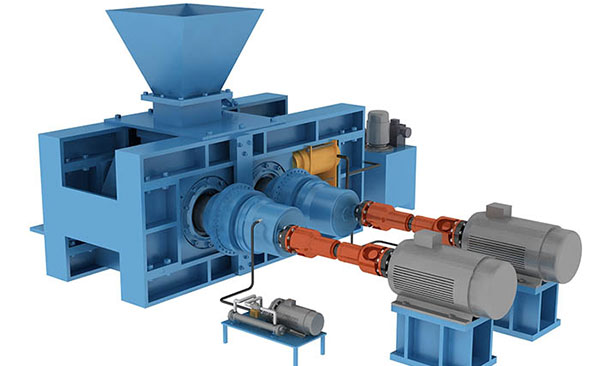

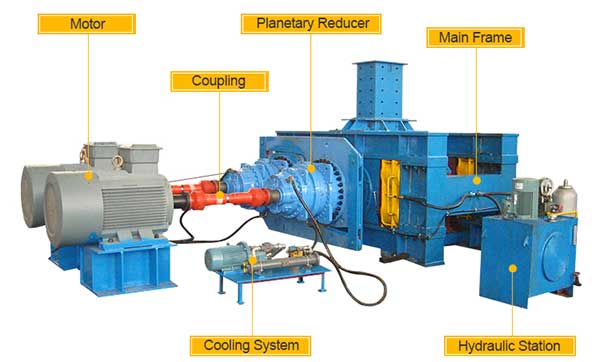

Structure

Features in ore mining

High pressure roll grinding is normally used as super fine crushing process,which can be as the third or fourth stage of a crushing process, also can be used in the semi-autogenous grinding process for hard rocks.

The input material size for HPGR normally is 20~60 mm,and output size can be less than 3mm. The best input size and output can be chosen accordingly. There are several features compare to the traditional grinding process.

Big size reduction ratio

The output size from a normal crushing system is around 12mm, and the size reduction ratio around 5. But the size reduction ratio of HPGR can be up to 10 or even more. It is able to reduce the ore from size 20-70mm to below 3mm.

High crushing efficiency, low energy consumption

Ores output from HPGR are with high ratio of fine particle, and the internal of the ore will have a lot of micro cracks. More fine particle and micro cracks will help to highly reduce the ore grinding cost. Compare to the crushing system which is made of cone crusher, rod mill, ball mill, for an HPGR system is with lower energy consumption for 20 to 50%.

Significantly improve the follow-up process like flotation, leaching, etc.

According to the practice of HPGR in the copper and gold mining industries. The micro cracks in the ores made by HPGR significantly improve the ore grinding efficiency, increases the mineral liberation degree, improves the flotation performance, and increases the recovery ratio of final concentrate ores.

In the leaching process, the micro cracks make the ore a better contact with the leaching liquid, which significantly increases the ore leaching ratio. According to the research on copper ore leaching, by using the HPGR, the copper increases for 60% and leaching ratio increase for 2% to 6% compared to traditional crushing process.

Greatly improve diamond recovery rate in diamond project

The traditional grinding machinery like ball mills, semi-autogenous grinding mills or other crushers reduce the particle size by impact, which will destroy the large diamonds. It causes great loss of the diamond value, and also increases energy consumption.

When using HPGR on crushing the diamond ore, the rolls gap can be adjusted (e.g. 25mm) to ensure that the large diamonds won’t be crushed. Unique material layer grinding technology deeply squeezes the lean ore, which can increase the product recovery rate by more than 20%.

Roll surface with good abrasion resistance, simple structure and easy maintenance

The roller surface is made of powder metallurgy (PM) alloys with good abrasion resistance. The segment service life for hardness ore normally is 6,000 to 10,000 hours while for medium-low hardness iron ore is 10,000 to 18,000 hours.

The equipment is compact in structure, with small dimension, easy to operate and maintain, and easy for automatic work and monitoring. The practical annual working time of a HPGR can reach 7,000 h, which is much higher than normal crushers.

Parameter

| Model | Roll diameter (mm) | Roll width (mm) | Power (kW) | Input size(mm) | Output size(mm) | Capacity (t/h) | Weight (T) | ||

|---|---|---|---|---|---|---|---|---|---|

| mineral ore (mm) | iron ore concentrate (m2/g) | mineral ore (mm) | iron ore concentrate (m2/g) | ||||||

| GM600-200 | 600 | 200 | 2*75 | ≤25 | 1100-1300 | ≤3 | 1400-1600 | 16-24 | 14 |

| GM800-350 | 800 | 350 | 2*132 | ≤30 | 1100-1300 | ≤3 | 1400-1600 | 50-65 | 24 |

| GM1000-300 | 1000 | 300 | 2*160 | ≤35 | 1100-1300 | ≤3 | 1400-1700 | 61-91 | 32 |

| GM1000-400 | 1000 | 400 | 2*200 | ≤35 | 1100-1300 | ≤3 | 1400-1700 | 80-120 | 36 |

| GM1000-500 | 1000 | 500 | 2*280 | ≤35 | 1100-1300 | ≤3 | 1400-1700 | 100-150 | 40 |

| GM1200-500 | 1200 | 500 | 2*315 | ≤40 | 1100-1300 | ≤3 | 1600-1800 | 130-190 | 56 |

| GM1200-630 | 1200 | 630 | 2*400 | ≤40 | 1100-1300 | ≤3 | 1600-1800 | 160-240 | 65 |

| GM1200-800 | 1200 | 800 | 2*500 | ≤40 | 1100-1300 | ≤3 | 1600-1800 | 200-310 | 79 |

| GM1400-800 | 1400 | 800 | 2*560 | ≤50 | 1100-1300 | ≤3 | 1600-1800 | 260-390 | 110 |

| GM1400-1100 | 1400 | 1100 | 2*800 | ≤50 | 1100-1300 | ≤3 | 1600-1800 | 360-540 | 133 |

| GM1700-1100 | 1700 | 1100 | 2*1000 | ≤60 | 1100-1300 | ≤3 | 1600-1800 | 530-800 | 179 |

| GM1700-1400 | 1700 | 1400 | 2*1250 | ≤60 | 1100-1300 | ≤3 | 1600-1800 | 670-1000 | 208 |

Contact Us