Quick lime powder is a kind of powdery waste produced in the production of the lime kiln. The price of quick lime powder is very low, which is basically less than half of the price of lump quicklime. But in the production process of lime kiln, the production rate of quicklime powder is very high, many of the lime powder kilns have an ash content of more than 20%. The inefficient use of these lime powders will not only cause economic waste, but also cause pollution to the environment.

Where the quick lime powder comes – resources

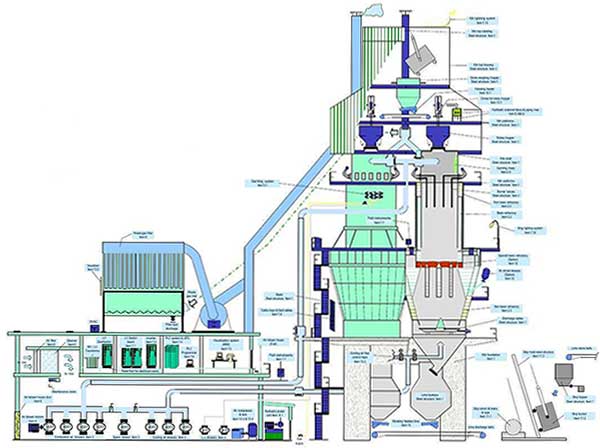

Take the Maerz Kiln as an example, lime dust is produced in 6 steps.

Raw material

The raw material – limestone entrained with stone powder and gravel. These pieces of material are easily nodulated when they are calcined inside the kiln, and these stone powders and crushed stones will become quick lime powder after calcination.

Kiln calcination

From the kiln top to the discharge platform, the friction and impact between the stones (sometimes higher than 10 meters) plus the physicochemical changes in the internal calcination of the kiln will produce stone powder which will become quicklime dust after calcination.

The reason for the dust generation here is often because the adjustment of the process parameters is unreasonable, the frequency control of the kiln top vibrating feeder is not good, it will be easy to generate a large amount of impact and friction between the raw materials. Then produce more powder than expected.

If you want to know how physicochemical changes occur in the lime kiln and produce ash, you need to analyze the limestone calcination mechanism.

It is generally believed that limestone with a coarse grain structure has a small absorption heat expansion ability due to tight grain combination, and is easily broken and pulverized during the calcination process, causing an increase in ventilation gas resistance and a decrease in yield. Expansion occurs in the 800 ° C limestone crystal below the demarcation point, causing cracks in the highly crystallized limestone and being fragile. There are also some very large crystal grains which are heated to expand into a powder state.

Discharging platform drop

If the hydraulic speed of the unloading platform was too fast or a large drop will also lead to the generation of quicklime dust.

Unloading bin vibration

From the ash discharge silo at the bottom of the kiln to the conveyor, dust is generated when passing the vibrating feeder.

Finished warehouse screening

From the conveyor to the finished product bin, the vibrating screen separates the quicklimes with different particle sizes into different finished product bins. When the vibrating screen is sieved, with large amplitude and fallen lime will generate lime dust.

Transportation

In the case of bumping, wind erosion, etc. on the road during loading, unloading and transportation of the load trucks, dust is generated.

Improvement to reduce dust rate

Different improve measures can be taken at different stages in the lime production process to reduce the rate of quick lime dust.

Raw materials

In view of the phenomenon of entraining stone powder and crushed stone in limestone raw materials, the quality of raw materials should be strictly controlled, the size of raw materials entering the plant is with certain range (40~80mm), powders and oversized blocks should be prevented. Buffer devices should be installed at all raw material transfer stations.

Kiln calcination

The phenomenon of powder production from the top of the kiln to the discharge platform requires reasonable adjustment of the process parameters, the frequency of the kiln top vibrating feeder should be controlled within a suitable range to reduce the generation of powder during transportation.

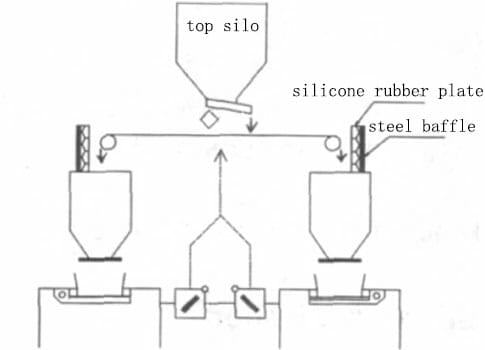

The 500t/d kiln body is a fixed funnel due to the kiln top loading method. A retaining steel baffle plate is arranged above the hopper, and a silicone rubber plate is arranged in front of the baffle to reduce the generation of powder during the reversible conveying process. This not only greatly improves the fabric in the kiln, but also improves the phenomenon that the stone washes the funnel and produces the powder.

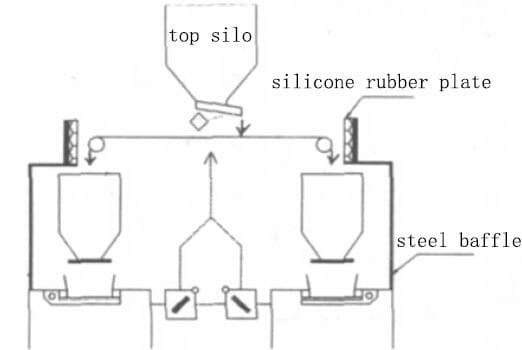

The 600t/d Maerz lime kiln top charge is a rotating funnel type. Due to the impact of the stone material and the rotating silo wall during the blanking process, the friction is severe, and more powder is produced than the 500t/d kiln fixed funnel. And because the 600t/d kiln charging funnel is rotary, it is not possible to place the baffle plate and the silicone rubber plate on the funnel like the 500t/d kiln. Only the steel plate can be connected from the kiln body above the rotating funnel. Retaining the steel baffle plate, a silicone rubber plate (Photo as below) is placed on the front of the baffle. This improvement can greatly reduce the mutual impact between lime and stone impact hopper, and reduce the lime dust ash rate.

In addition, it can also meet the high output according to the process requirements, and the height of the material in the kiln can be controlled by parameter adjustment, thereby reducing dust rate where of excessively large drop during the loading process.

Discharging platform drop

Make the hydraulic speed of the unloading platform reasonably. For example, to adjust the hydraulic cylinder from 30s to 40s per cycle, which can reduce the generation of dust.

Unloading bin vibration

Adjust the frequency of the vibrating feeder on the kiln bottom ash discharge bin to 30~35Hz, and optimize the feeding way.

Finished warehouse screening

Reduce the amplitude of the vibrating screen in a more reasonable range.

Transportation

In the process of loading and unloading, strictly follow the operating procedures to minimize the amount of dust generated;

Use shelter cloth cover on the truck or use cans to put the quicklime dust, this will not only reduce wind erosion, but also protect the environment.

These methods can reduce the rate of dust generation, but can not avoid the generation of dust. For the optimized whole lime kiln production line, the remaining dust still needs to be utilized. The dust can be recovered using a quick lime briquetting machine.

Quicklime briquetting machine

Quick lime briquetting machine is a roll-type device that presses the lime into a certain shape for storage and further use.

Working principle

The raw quicklime passing through the pre-pressing screw into the middle of the roller set, then the material is briquetted by the counter roller running at the same speed and reverse direction. When briquetting, the unit forming pressure in the material is changed from small to large, and is formed at the center line of the two rollers with the maximum pressure. After the material passes the middle, the unit forming pressure gradually becomes smaller and the material enters the off-briquette state until the briquette is output from the rollers.

When the speed of the main machine and the pre-press is adjusted properly, the briquette can be made once. The sieved small material can be returned and mixed with new materials to be briquette again.

The whole machine can be divided into 4 parts: pre-press part, main part, screen part, and hydraulic station part.

The shape and size of the finished briquette can be adjusted according to the needs. The selection range is large, the shape of the briquettes usually are the pillow, semi-cylindrical, egg, rod, apricot core and small grain, etc.

After the quick lime powder is briquetted, the utilization rate can reach up to 100%. The lime resources are effectively utilized to improve the overall economic benefits and further protect the environment.