With the development of the global economy, the gradual depletion of various mineral resources, besides, it also caused a variety of serious environmental problems, these have become factors that constrain the development of the global economy.

Countries all over the world are now doing a lot of work in environmental comprehensive management and developing circular economy. Now the global mainstream is the development and application of energy saving and emission reduction technologies.

Metallurgical briquette producing is an important part of the metallurgical process.

It can not only improve the metallurgical physicochemical properties of materials, but also an important way to realize the utilization of industrial solid waste resources and recycling economy.

Cold briquetting technology can not only improve its combustion or reaction performance, but also reduce the formation and emission of pollutants through the addition of additives.

It is an important way to achieve energy conservation, environmental protection and the use of waste resources.

The necessity of cold briquetting and its technological process

The necessity of cold briquetting

With the development of global industry, there are fewer and fewer high grade ore in the world.

As a processing method of mineral powder, the processing of mineral powder used in the metallurgical industry generally uses sintering or briquetting.

In these processes, the most important problem to solve is environmental protection, that is, how to deal with a large amount of dust ash or metallurgical sludge.

Like the fly ash, it contains many useful ingredients that can be used in smelting, an average of about 25%, but when it is directly used in the furnace for smelting, it will easily lead to energy loss and even smelting safety accidents, therefore, briquetting process is particularly important.

The cold briquetting process

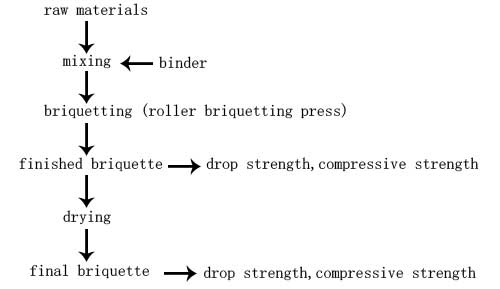

The cold briquetting is a way in which all the materials required in the production of the metallurgical industry are uniformly mixed, then subjected to a roller briquetting press for the cold briquetting work, and dried at a low temperature to get the finished briquette.

cold briquetting process

cold briquetting processPhysical and chemical indicators of cold ball briquette

The physical and chemical indicators of cold ball briquette mainly are as follow:

Wet briquette drop strength

The original wet briquette needs to take the process of screening and transporting to the drying house, a certain drop strength is required to ensure that there is no breakage during transportation and little deformation.

Finished briquette drop strength

The briquette dried by the dryer has to be transported many times and finally dropped into the furnace. Sufficient drop strength is required to ensure that there is no breakage and few deformations during transportation.

Briquette compressive strength

Briquette must have a certain compressive strength to withstand the various stresses of the briquette during the drying process, such as the upper layer pressure of the drying, the stacking pressure of the storage silo, etc.

Heat strength

Briquette must have a certain heat strength during the sintering process, otherwise it will break and pulverize.

Porosity

Porosity is the percentage of pore volume in the volume of briquette to the total volume of the briquette.

The size and distribution of the pores are closely related to the strength of the briquette. As the porosity decreases and the grain radius shrinks, the briquette strength increases.

Reduction

The briquette reduction is the volume expansion of the briquette when it is reduced in the furnace and the strength of the briquette after it has been reduced.

Generally, the reduction degree of briquettes in the furnace is up to 60%, and the residual cold compressive strength after reduction is not less than 25 kg /cm2.

High temperature softening and melting

Briquette will be reduced during the smelting process and will gradually melt as the temperature increases.

In order to avoid the expansion of the viscous melting zone, it is required that the briquette softening zone should not be too wide and the melting point should not be too low.

The benefit of cold briquetting

Realizing circular economy

The traditional smelting process is to smelt the lump raw material and the lump coke into the electric furnace at the same time. These lumps will be pulverized when heated, while 20% to 30% of the useful components are collected by the dust collection system.

Take the dust from manganese alloy process as an example, the content of MnO in the general soot is as high as 2% to 30%.

The use of cold briquetting can achieve secondary utilization of dust and achieve the purpose of circular economy.

Reduce the consumption of reducing agent and energy

Coke (coal) is used as a reducing agent to directly reduce MnO during the ferromanganese smelting process.

In the traditional smelting process, raw materials and reducing agents contact by the way of point contact.

But cold briquetting combines the mineral powder and coke (coal) together as briquette for smelting and reduction. The mineral powder and reducing agent are in surface contact, with a large contact area. It makes the carbon-containing briquettes have the characteristics of fast reaction and high melting efficiency.

For example, use 20% carbonaceous briquettes in the blast furnace charge (briquette with 5% of coal), the blast furnace smelting coefficient is increased from 1,485 t/m3·d to 1,831 t/m3·d, the furnace coke ratio was reduced from 789 kg/t to 711kg/t. The same effect is obtained when the ferromanganese alloy is smelted in an electric furnace.

Cold briquetting technology has broad prospects in the metallurgical industry.

Whether in steel plants or ferroalloy plants, the use of secondary metallurgical resources of fine ore and solids has become an important task in the efficient use of mineral resources and environmental protection.